Houston DPF Inspections

Houston DPF cleanings

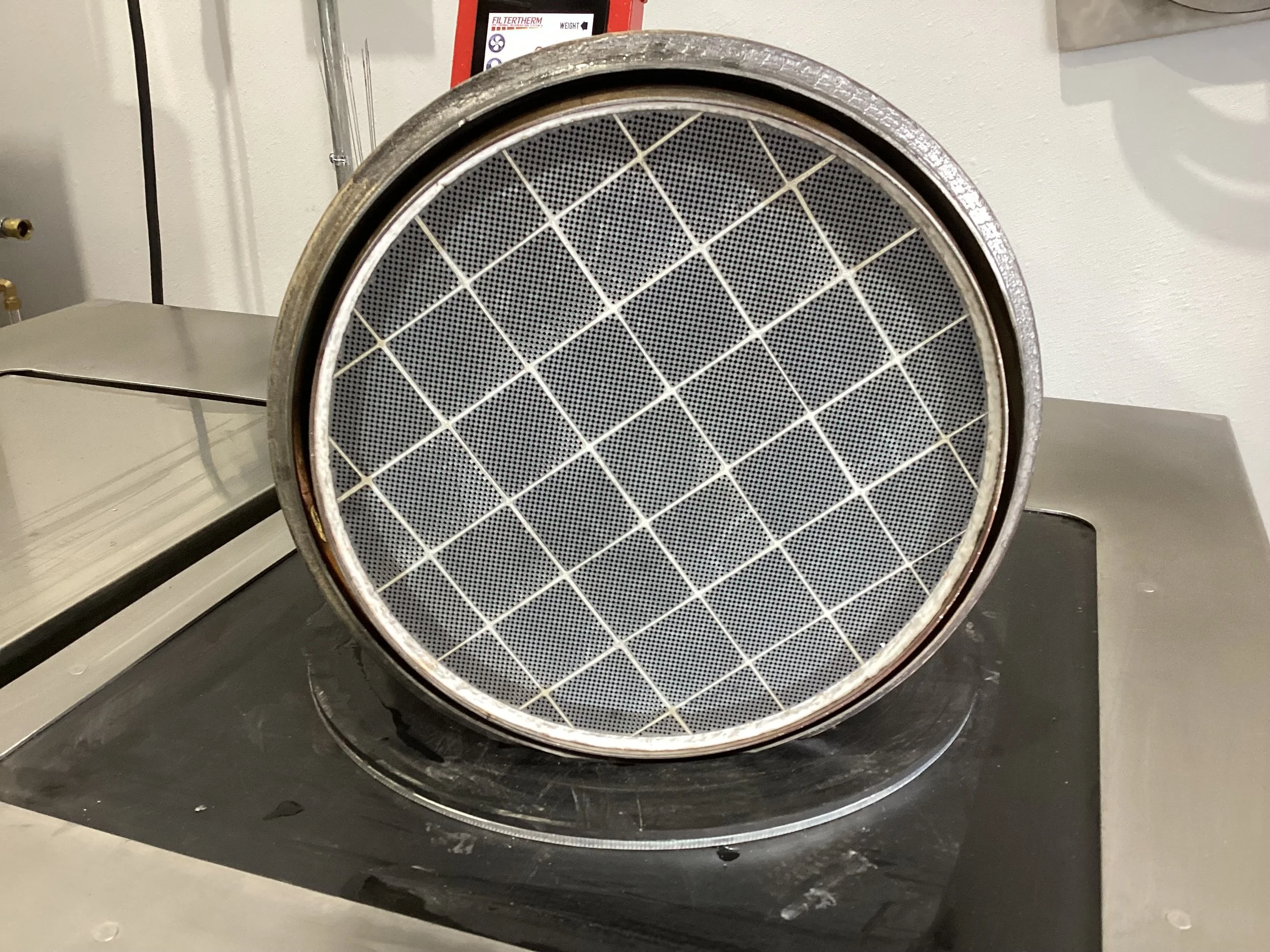

Our DPF inspection process is a critical step in assessing the current operational performance of a DPF upon arrival in our shop. Utilizing the Filtertherm Inspection Table, this process becomes systematic and efficient, allowing for a thorough evaluation of the DPF’s condition.

The inspection begins with our team using our physical inspection to conduct first a visual inspection of the DPF and/or DOC. The table is designed to accommodate various sizes and shapes of DPFs, providing a stable platform for the inspection process. The technician looks for any signs of external damage, such as cracks, evidence of soot or ash passthrough, or other deformities that might indicate internal damage.

Next our equipment is designed with a built-in scale that measures the weight of the DPF. This weight is compared to the manufacturer’s specifications for a clean DPF. An unusually heavy DPF might indicate excessive soot or ash accumulation, which could signal the need for cleaning or replacement. This metric is then recorded for post-cleaning comparison and reporting requirements.

A flow test is then conducted to assess the DPF’s ability to allow exhaust gases to pass through. The Inspection Table is integrated with a flow meter that measures the air flow through the DPF. The results are compared against standard benchmarks to determine if there is any blockage or restriction in the filter.

The Inspection Table is equipped with a digital interface that allows the technician to log and store inspection data in our proprietary system which tracks every DPF and DOC we service. This includes visual observations, weight measurements, and flow test results, technician notes, and photos of every service. The data is then stored for future reference and is used to generate our reports which are provided to every customer after every cleaning.

Our technician will also perform a pin test in which a small pin is inserted into the unit to determine the level of blockage in the internal cells of the DPF. This will also be noted in pre, and post cleaning reports issued to the customer.

If not, the technician may recommend cleaning or replacing the filter. Precision DPF can assist in determining the best solution for both scenarios. If the filter needs to be replaced, we can source a band-new replacement at substantial discounts over the dealership.